WELCOME

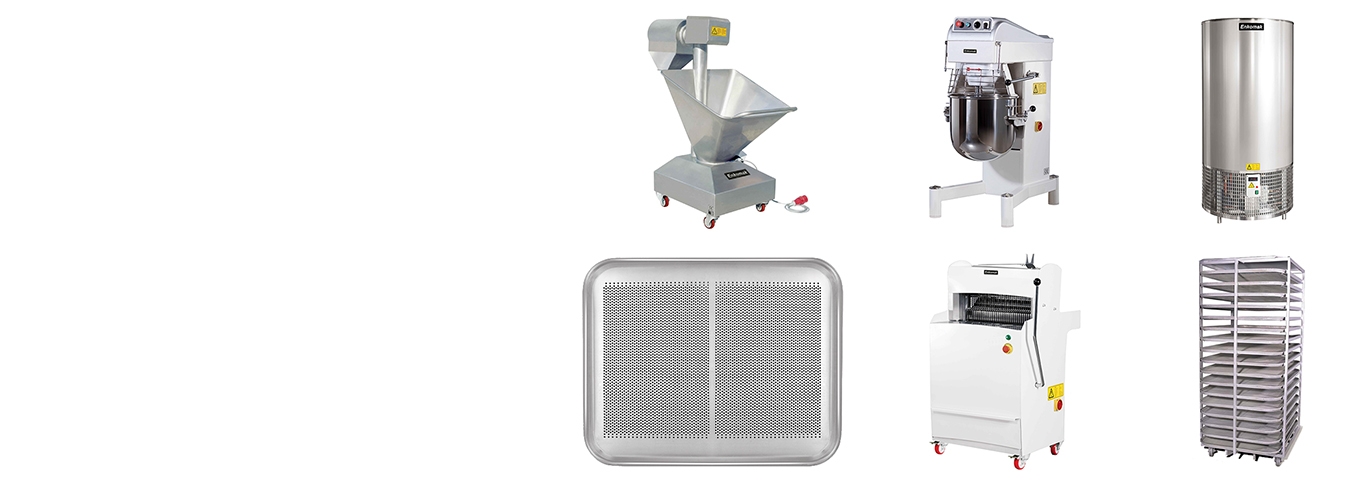

We represent our experience and knowledge in food processing industry with the machines that we are producing and selling to our valuable customers. Today, with the 30 different models in the portfolio of bakery and pastry equipment, we become a leading and one of the most trustable manufacturer within our industry. We encourage you to have a look at our wide range products presented in the website. Hope to see you as an ATS customer soon.

More